Hi folks,

Back in the late 1980's in Australia, someone, somehow, imported 200 C5's and sold them through a bike store in the Sydney suburb of Granville. A family friend bought one of them, and as a kid I had the privilege of riding around in it a bunch of times.

I think this particular C5 was about a year old (I'd say this was around 1988/1989?) when someone took a right hand turn quite fast and tipped the poor C5 onto its side. I'm told this caused the original battery to fall out, and lead acid leaked out all over the place, etc, etc... Long story short, the C5 was put into storage, and that was that. (oh, and the battery, cover plate, and charger are long gone!)

Fast forward a few decades, I'm now living in Singapore, and seeing said C5 owning friend once or twice a year... Each time I see him, I've been hassling him about his C5. I had fond memories of riding around in it, and decided it was time to bring it back to life. I've spent at least six years twisting his arm, and patiently waiting and waiting. Earlier this year, over a huge pot of Singapore Chilli crab, he finally, relented and said I could have it. Result!

Anyway, once back in Aus, here's what he delivered:

Not great, but not bad either. No tyres or tubes, no battery or cover plate, but otherwise intact. It also looks better now, after a wash :)

(here's one for the 'trainspotters' who want to know which batch were imported to Australia. It has a dark grey boot.)

Now, onto business. First of all, the chain tensioner was a disaster, so I've sourced a new one, and a new spring.

I also managed to get one of those battery wiring kits from c5alive all the way to Sydney, and with my brother being the arms and legs, and me in the background on Skype video with some wiring diagrams handy, we fitted it and attached a battery.

No dice.

After checking around with a multi meter to test the fundamentals, and discovering that the motor switch wasn't really getting any voltage, this was discovered:

[img=http://exodus-online.com/uploads/IML337/sinclair/altAtJ0KPlqeGQDR48ikJGJSaS3J1rnUlzaublVb11Nzz0O.jpg]D1[/img]

Oops. Given the electronics on the board look fairly straightforward, with components that can still be obtained, we'll just get this looked at by someone who is handy with a PCB and a soldering iron :) Though, I've found other examples of D1 blowing, but none of them have been so 'violent'! Hopefully the PCB isn't damaged and we can salvage it.

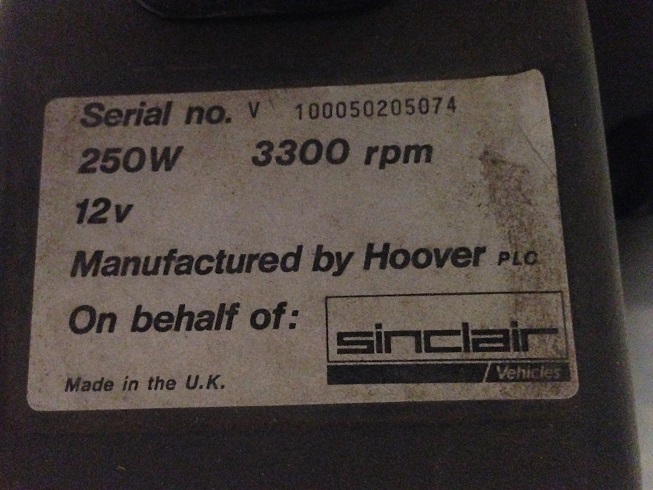

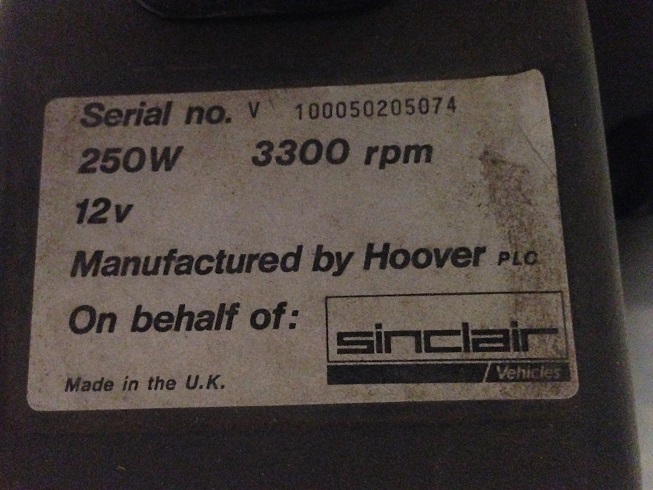

So, while getting that looked at, I do have a question... What's the best way to test the motor in a C5? We disconnected the motor from the Control Box and applied 12v directly to it, but nothing happened. Any advice on how I can validate the state of the motor independent of the rest of the C5?

Thanks!

Back in the late 1980's in Australia, someone, somehow, imported 200 C5's and sold them through a bike store in the Sydney suburb of Granville. A family friend bought one of them, and as a kid I had the privilege of riding around in it a bunch of times.

I think this particular C5 was about a year old (I'd say this was around 1988/1989?) when someone took a right hand turn quite fast and tipped the poor C5 onto its side. I'm told this caused the original battery to fall out, and lead acid leaked out all over the place, etc, etc... Long story short, the C5 was put into storage, and that was that. (oh, and the battery, cover plate, and charger are long gone!)

Fast forward a few decades, I'm now living in Singapore, and seeing said C5 owning friend once or twice a year... Each time I see him, I've been hassling him about his C5. I had fond memories of riding around in it, and decided it was time to bring it back to life. I've spent at least six years twisting his arm, and patiently waiting and waiting. Earlier this year, over a huge pot of Singapore Chilli crab, he finally, relented and said I could have it. Result!

Anyway, once back in Aus, here's what he delivered:

Not great, but not bad either. No tyres or tubes, no battery or cover plate, but otherwise intact. It also looks better now, after a wash :)

(here's one for the 'trainspotters' who want to know which batch were imported to Australia. It has a dark grey boot.)

Now, onto business. First of all, the chain tensioner was a disaster, so I've sourced a new one, and a new spring.

I also managed to get one of those battery wiring kits from c5alive all the way to Sydney, and with my brother being the arms and legs, and me in the background on Skype video with some wiring diagrams handy, we fitted it and attached a battery.

No dice.

After checking around with a multi meter to test the fundamentals, and discovering that the motor switch wasn't really getting any voltage, this was discovered:

[img=http://exodus-online.com/uploads/IML337/sinclair/altAtJ0KPlqeGQDR48ikJGJSaS3J1rnUlzaublVb11Nzz0O.jpg]D1[/img]

Oops. Given the electronics on the board look fairly straightforward, with components that can still be obtained, we'll just get this looked at by someone who is handy with a PCB and a soldering iron :) Though, I've found other examples of D1 blowing, but none of them have been so 'violent'! Hopefully the PCB isn't damaged and we can salvage it.

So, while getting that looked at, I do have a question... What's the best way to test the motor in a C5? We disconnected the motor from the Control Box and applied 12v directly to it, but nothing happened. Any advice on how I can validate the state of the motor independent of the rest of the C5?

Thanks!

posted on: 14/06/2014 09:45:14